Combined Heat & Power (“CHP”)

CHP systems have been in service for over 140-years, providing efficient, reliable electrical and heat energy. They are used in facilities such as hospitals, universities, government buildings, condominiums, greenhouses and factories.

By utilizing both the electricity generated as well as the heat produced by the CHP engine, fewer emissions are released into the air as waste exhaust.

CHP engines often run on natural gas or on bio-fuels, with some manufacturers able to operate their engines 100% on hydrogen, resulting in a zero-carbon footprint.

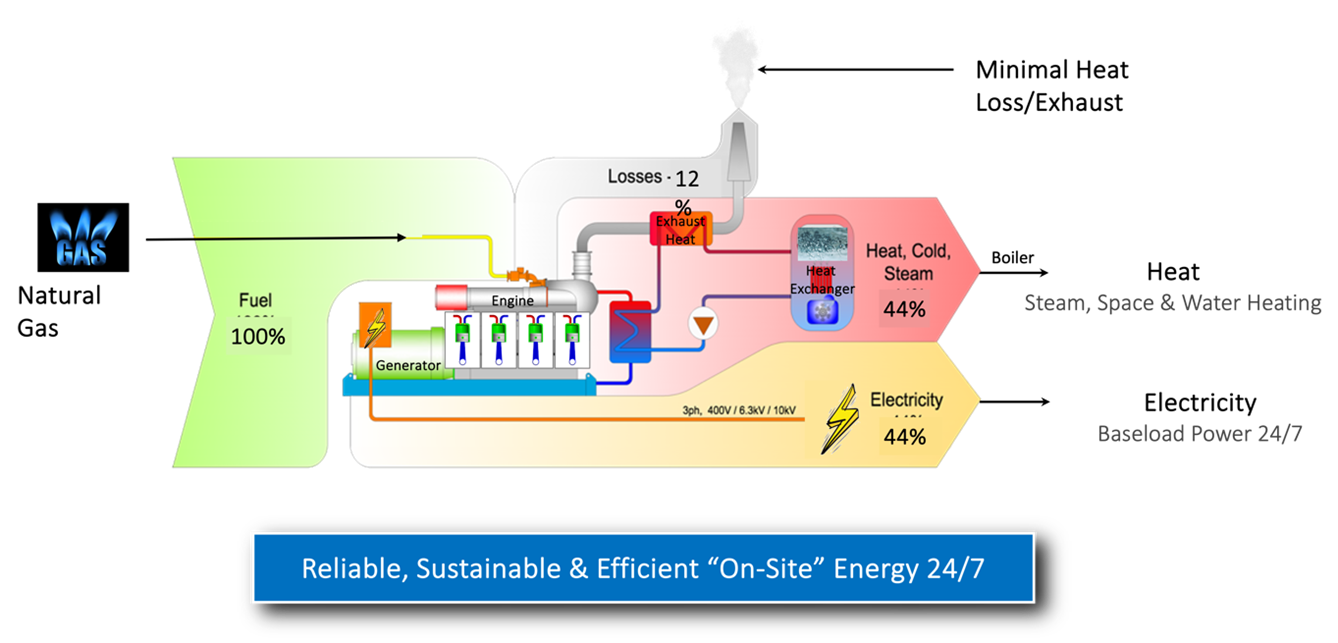

How does a CHP system work?

A CHP system is simply an engine connected to a generator, that creates electricity on-site.

When the engine is running, it builds up heat, and instead of exhausting that heat up the chimney, the engine heat is captured and can be used to pre-heat a facility’s boilers. This can extend the life of the boilers, as they don’t have to work as hard to heat the water. The heat can also be used for space heating or creating steam, which is often required in hospitals. (See diagram below.)

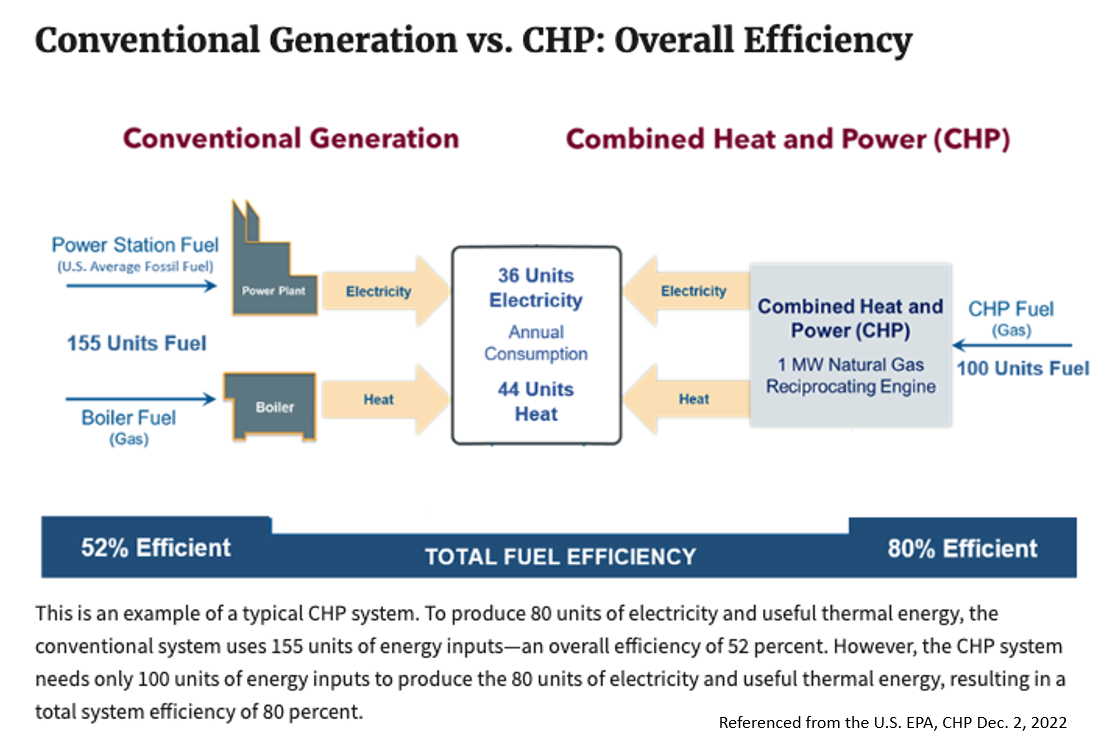

Every unit of fuel in a CHP system creates both electricity and heat. As such, the efficiency of a CHP system is roughly 88% versus only 44% in a conventional system (which obtains heat from a gas-fired boiler and electricity from a power generating station).

Benefits of a CHP System

- Save up to 20% on monthly energy bills

- Reduce carbon emissions by up to 30% (or more depending on fuel)

- Reliability – CHP is an on-site energy plant, reducing the reliance on the energy grid, providing energy security even in times of grid disruption

- Reduce transmission and distribution costs.

- Efficiency will increase to as much as 88% – with as little as 12% energy being exhausted up the chimney

Facilities Using CHP:

University of Toronto

6.0 MW

Queen’s University

15.0 MW

York University

10.0 MW

Markham District Energy

5.2 MW

Sunnybrook Health Sciences

8.0 MW

GTAA (Pearson Airport)

117.0 MW

Hamilton Health Sciences

22.75 MW

DelFrescoPure Greenhouses*

10.0 MW

(*CO2 is a by-product of CHP is used as fertilizer in greenhouses)

CHP systems create efficient, on-site electricity and heat (as a by-product). The electricity is provided to the Customer at a discounted rate to the monthly hydro rate, resulting in energy bill savings. By producing their own electricity on-site, the Customer requires less electricity from hydro. The customer is always connected to both the CHP system and to hydro, so there is always redundancy on the supply of electricity. CHP can support supplement an emergency generator to provide additional lighting, appliance usage and possibly additional elevators during a power outage.

With the global move toward a zero-carbon footprint, CHP engines, which today operate mainly on natural gas, can run on a blend of natural gas and hydrogen. And as hydrogen becomes commercially available, these engines can be outfitted to run 100% on hydrogen, leaving a zero-carbon footprint. ProPhase is agnostic as to the engine manufacturers, and works in conjunction with the facility’s corporate goals, to ensure the engine(s) selected meet the facility’s objectives and provide the cleanest and most-efficient systems available.